Tour Here, Get Your Tour!

Aly Bruno • February 10, 2021

The Tour You Didn't Ask For!

Take you on a tour of our workplace, you ask? Well if you insist! Please sit back relax and close your eyes for wonderful detail of our floorplan as you read away your worries. (Maybe have someone read this if you really want to close your eyes, but maybe don’t fall asleep.)

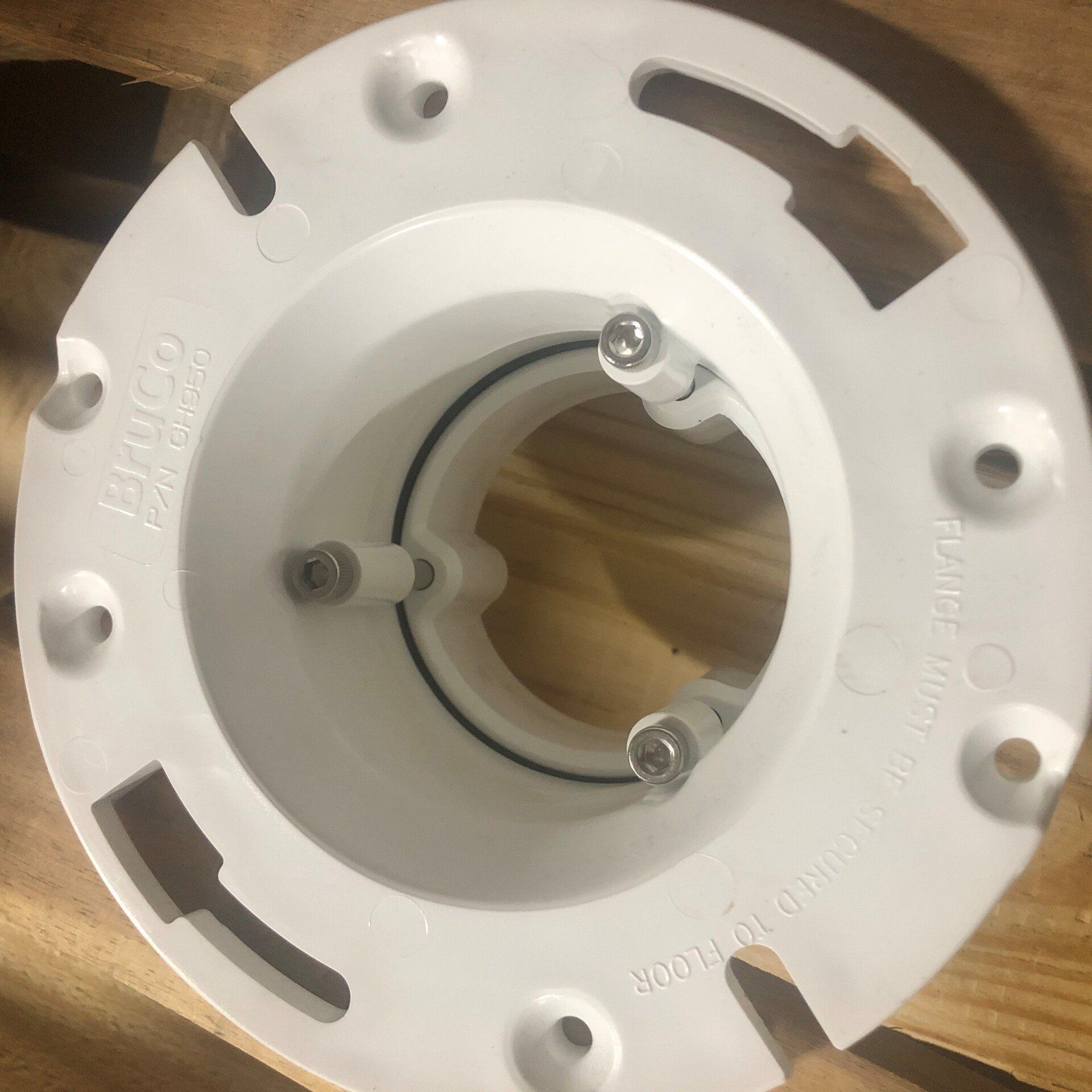

The big window of glass greets you as you push the doorbell to be let inside. Two chairs sit unoccupied with golf magazines for entertaining pleasure on a small table. Right in front of you hangs a glass etched logo of our business. ‘BruCo’ reflects from the light, underneath a display of plastic molded products injected by our machines. To the left and the right of you is a smattering of offices and a gray double door. You can hear the hum and clanking of the machines at work, sometimes even laughter roars above the steady commotion.

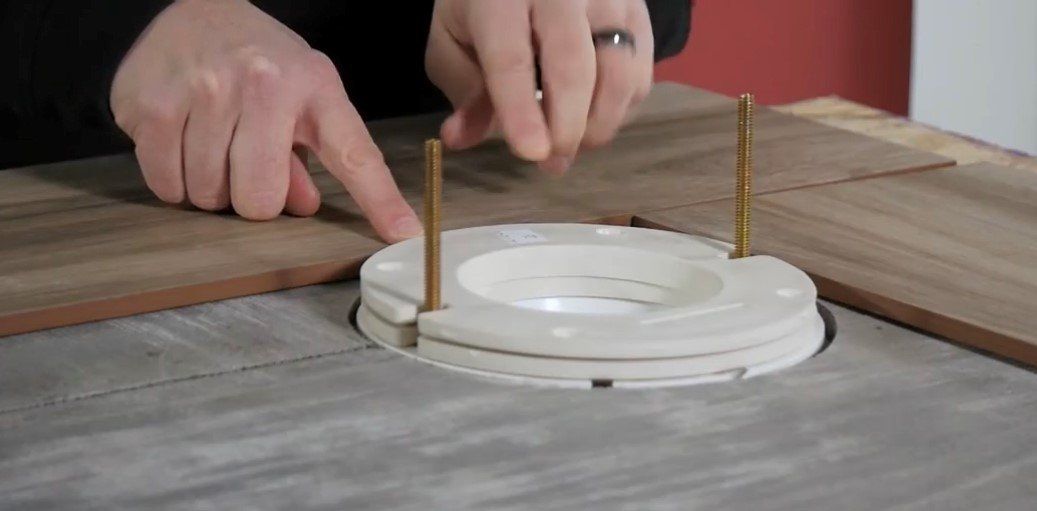

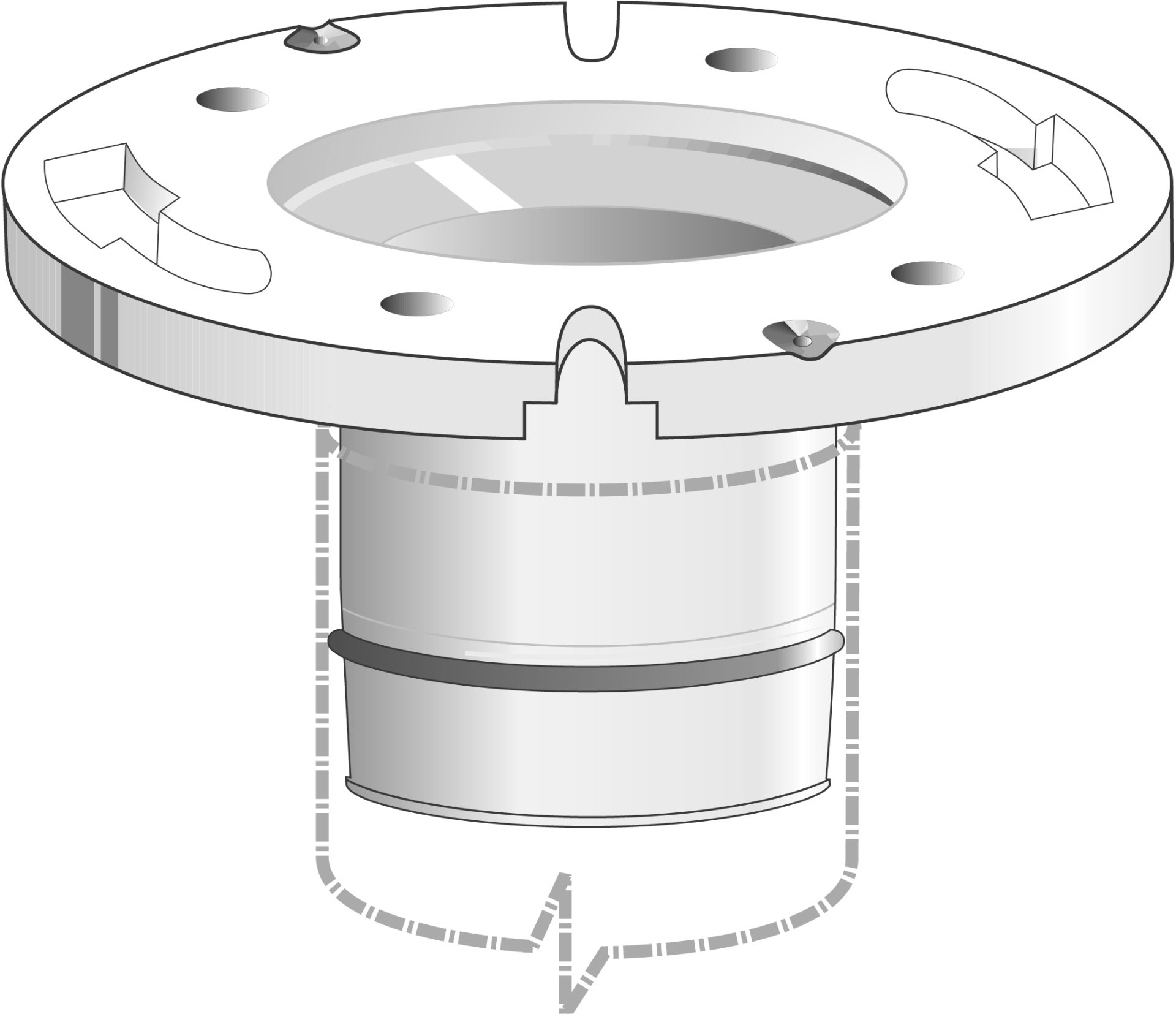

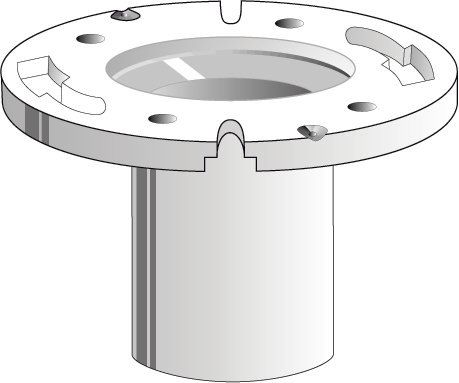

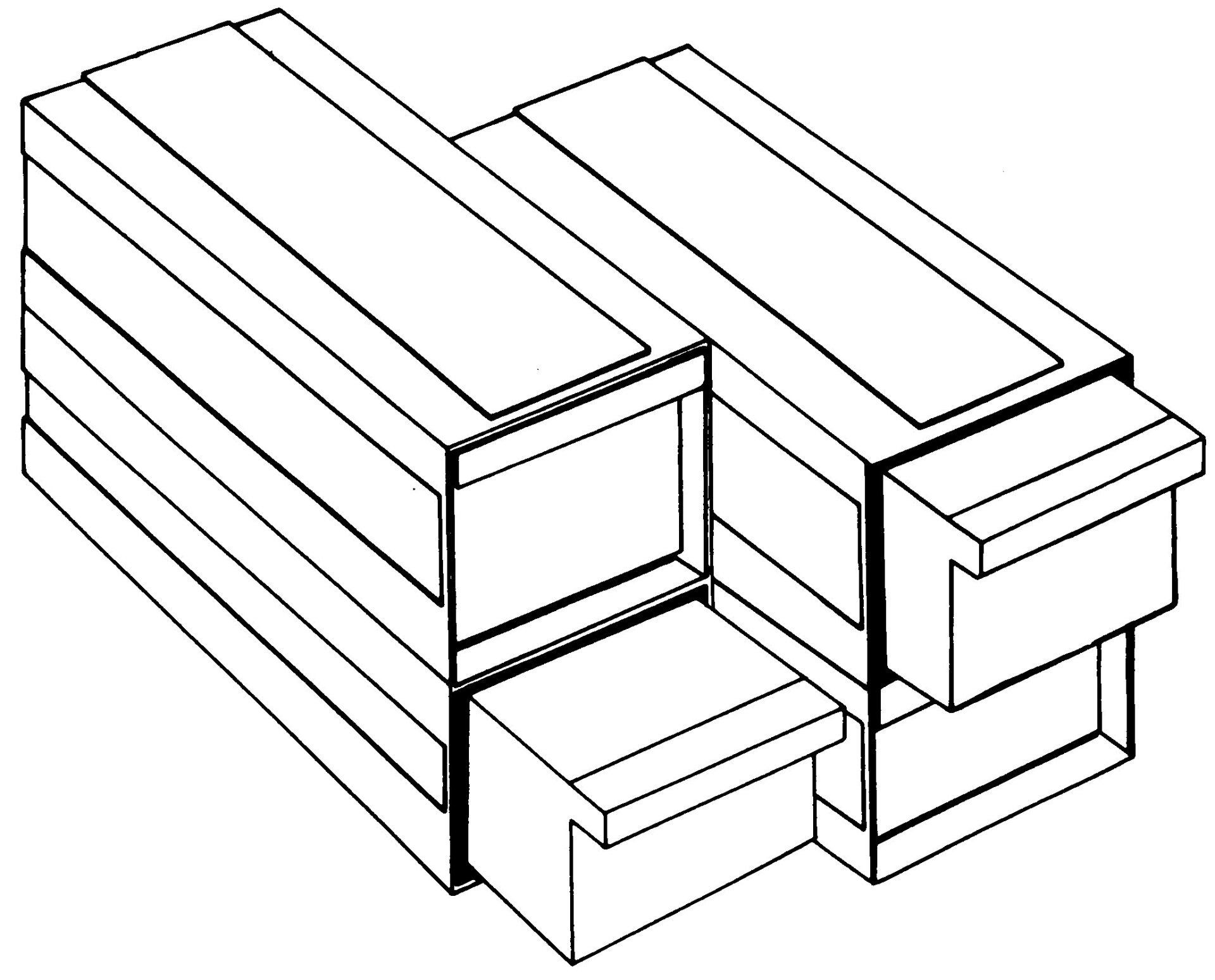

Inside the plant you enter to a break area full of tables and chairs with a fridge, food prep area, and lockers on the far wall. Beyond this you see stacks of production already ready to go, awaiting their delivery truck’s arrival. Veering left you drop down your safety glasses and see machines guiding a path down to the end of the facility. First hooks are being popped out as employees press nails into them and package them. The IF333P being taken from the machine to be cooled down for packing, and just ahead a smaller machine releasing black bands that will be purposed for combining parts. Up ahead a stack of organized boxes greets you while another employee assembles the bands to the GH950, gently screwing in each bolt for quality pressure. Nearing the end of the line of machines there’s more hooks being pushed out by another, similar machine and one right next to it doing the same, but with much smaller sizes. The employees have their rhythm, keeping up with the machine’s timed shots. Lastly, at the very end of machines, is the one with the robotic arm suctioning the CF250s and placing them on the conveyer belt for the final employee to let cool for boxing.

After all the entertainment from production, you take a turn around the shelving and find the stacks of finalized production are gone. Our shipper has already placed all of the delivery away in the truck that arrived just after the beginning of the tour. The area is clear only to be filled back up again by the next order that all the machines are eagerly releasing. In fact, you hear the forklift being turned back on and one of the foremen is getting an empty skid ready to replace a completed one. The circle of BruCo life goes on and you make your way back to the front, bump elbows with the boss and head back to your daily life as the blog writer, or whatever you do.